All New! XFR

Unbeatable Flexibility

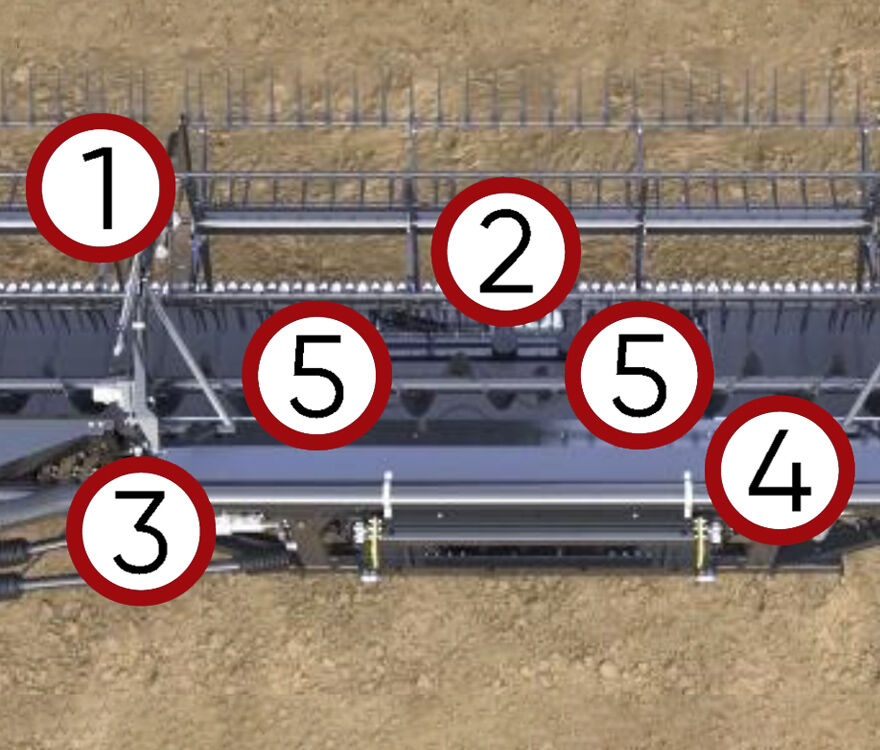

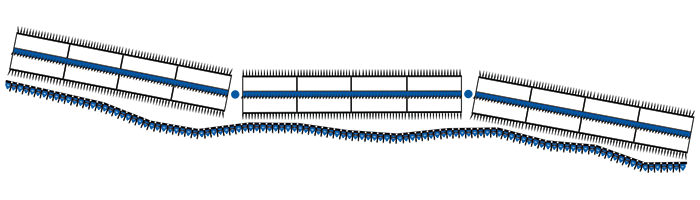

The XFR (XtremeFlex Razor) is the newest in our line-up of drapers. Our all-around draper is 50' wide and is equipped with a 3-section reel, 3-section frame and fully flexible cutterbar. The lightweight design of the wings maximizes the responsiveness in uneven terrain. The XtremeFlex Razor’s wings boast a flex ±7° for a total flex range of 52”. Designed for high volume harvesting with the widest center belt (87”) and feeder house opening, the XtremeFlex Razor maximizes harvesting with all models of larger combines.Available in 50 foot width only.

| Model | Width (Working / Outer) | Reel Type | Frame Type | Flex Range | Cutter Bar | Total Weight | |

|---|---|---|---|---|---|---|---|

| XFR 50 | 50' / 51' | 3-Section | Flexible | 52" | Flexible | 12,455 lbs |