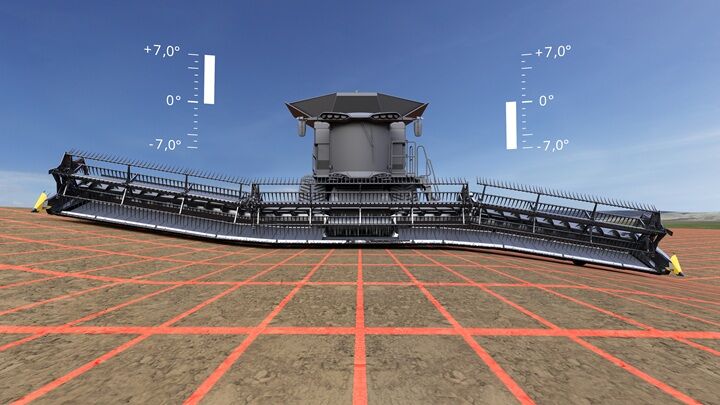

Framen & wheel flexible, rigid cutter bar

The new XF (XtremeFlex)

XtremeFlex in numbers

Technical Details

All numbers at a glance:

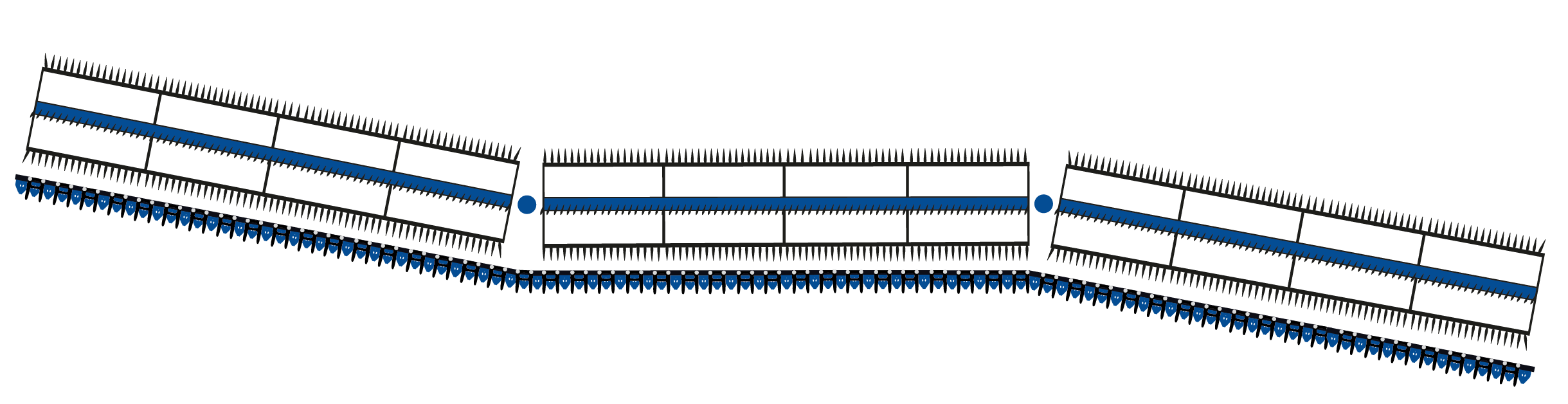

| Model | Working width | Reel | frame | Flexibility (Angle by 14°) |

cutter bar | weight |

|---|---|---|---|---|---|---|

| XF 35 | 10,65 m | 3-part | 3-part | 944 mm | rigid | 4860 kg |

| XF 40 | 12,20 m | 3-part | 3-part | 1130 mm | starr | 5040 kg |

| XF 45 | 13,70 m | 3-part | 3-part | 1310 mm | rigid | 5335 kg |

| XF 50 | 15,20 m | 3-part | 3-part | 1310 mm | rigid | 5922 kg |

Features

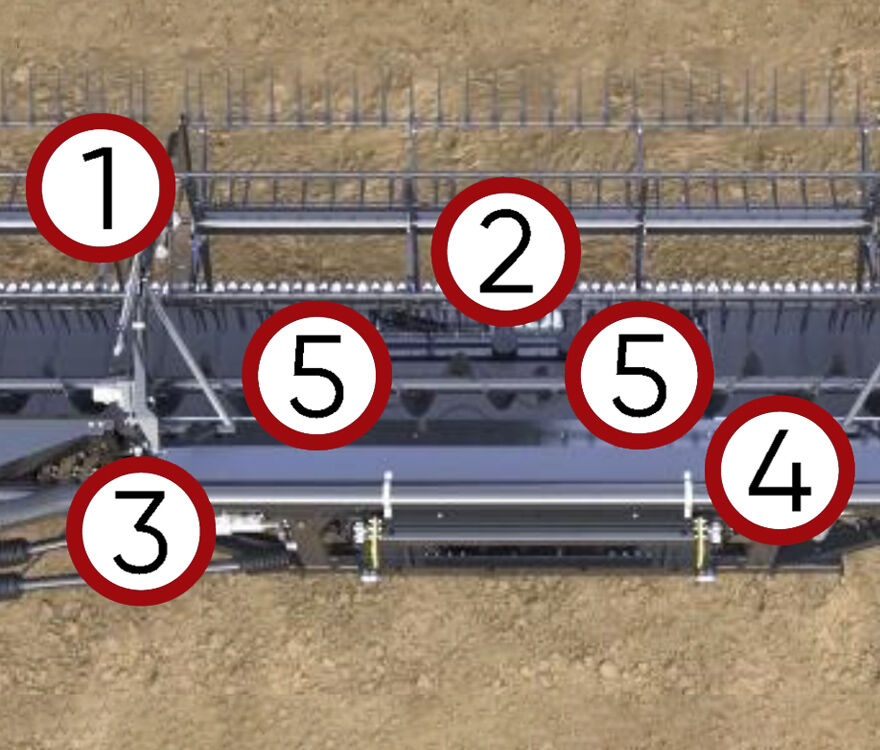

Centralized Drive Design

- Reel drive

- Central knife drive

- Hydraulic pumps

- Oil tank in frame

- Cross auger drive

Features

Floating Feeding Auger

Features

Wide Belts for Crop Flow

Features

Enhanced Reel and Tines

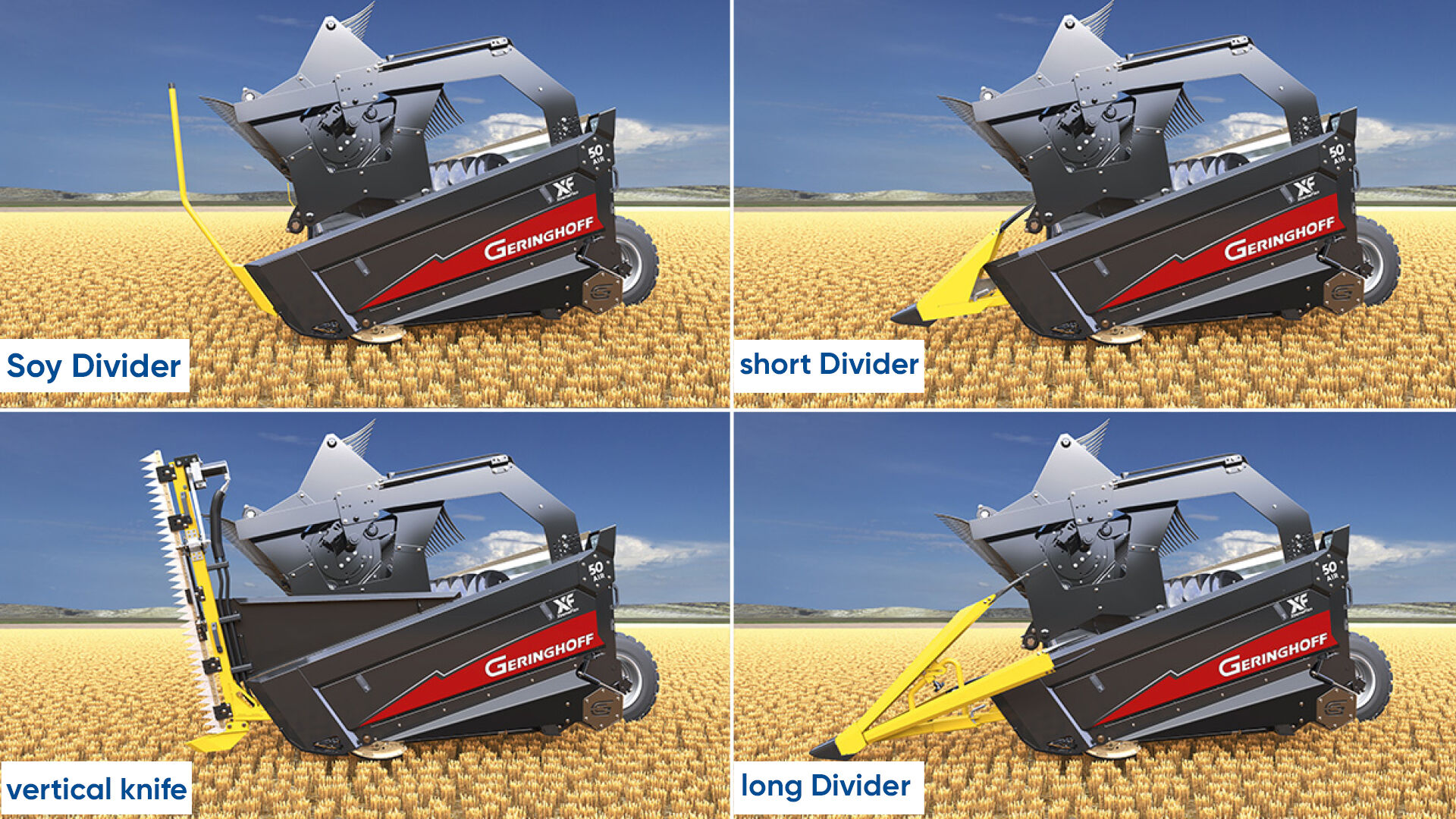

Crop Dividers

Key Advantages

- Clean cutting edges

- Helps reduce crop losses

- Quick and tool-free design prevents downtime

Canola Kit

Canola Kit

Key Advantages

- Optimal crop flow due to the large cross auger

- Brightly colored side knives holder for optimal visibility

- Quick and tool-free change of side knives prevents downtime

- Reduce crop losses with side panel extension

Maximize Your Yields

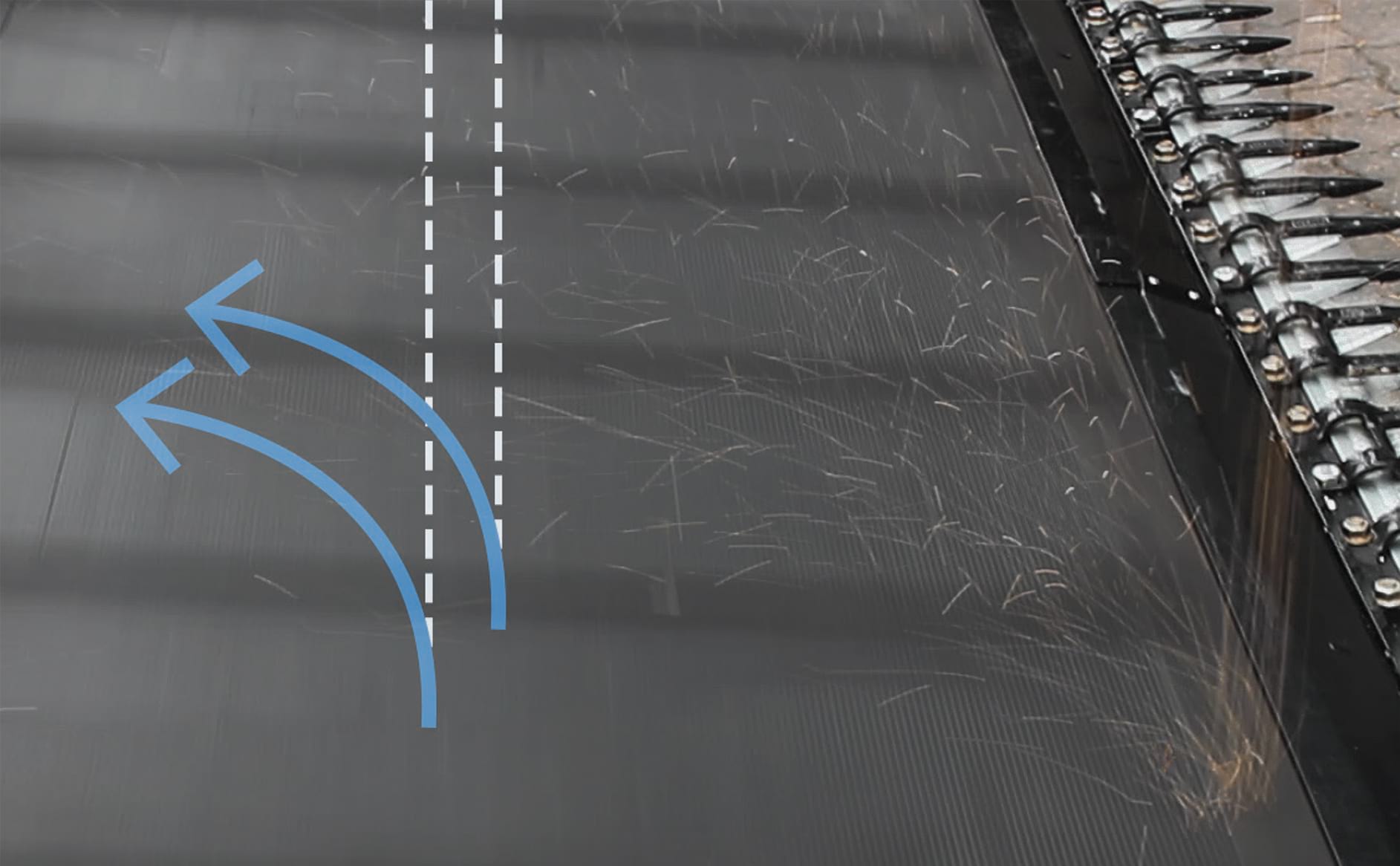

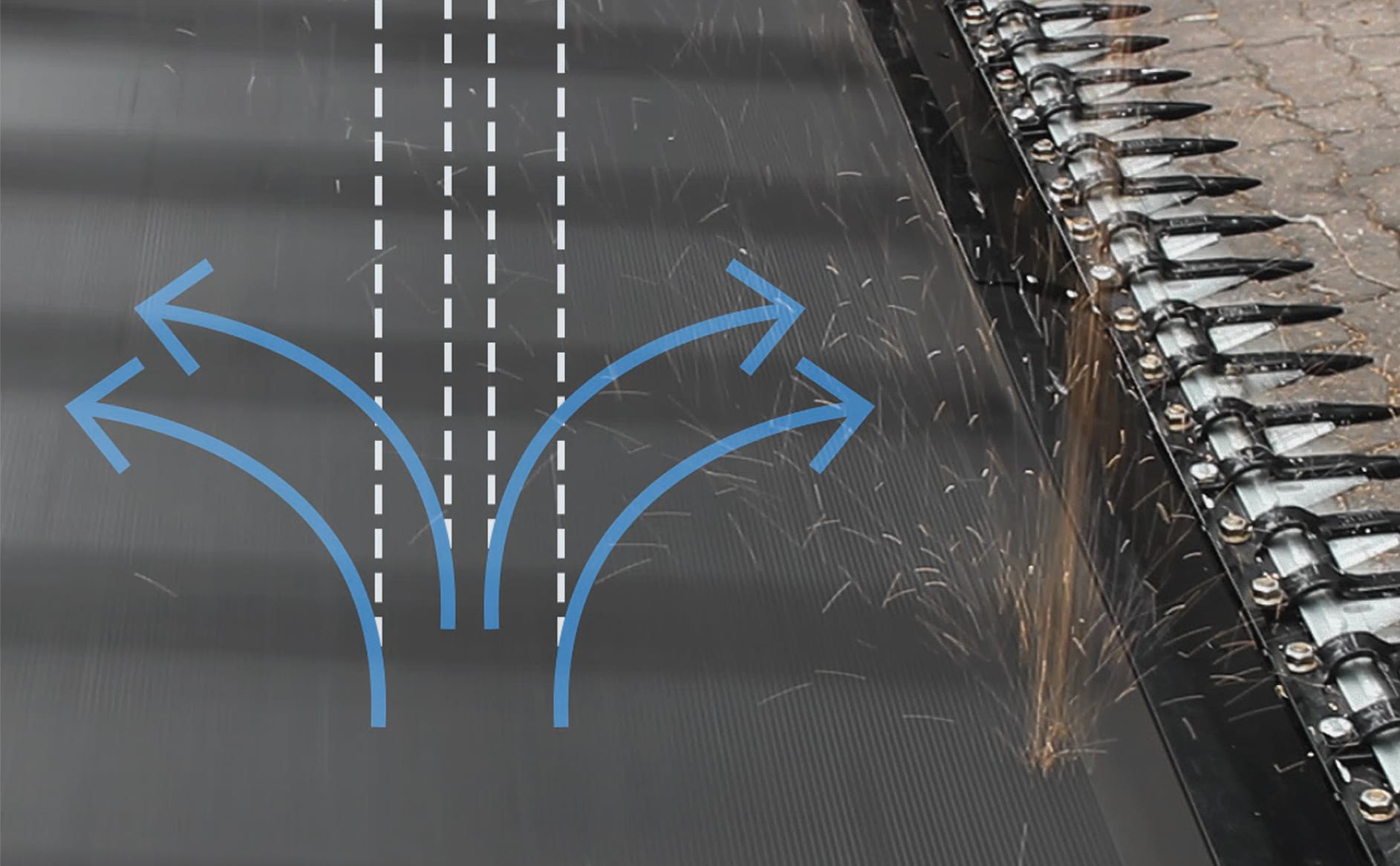

Integrated Air System (IAS)

Especially sensitive crops that tend to produce volunteers during their final phase of ripening require special harvesters that feature the appropriate technology to minimize losses caused by seeds and pods that have escaped the reel. That's why our Integrated Air System (IAS) is available on both the TruFlex and TruFlex Razor draper heads.Utilizing controlled airflow, our state-of-the-art IAS is precisely designed to maximize yields for sensitive crops. By blowing air in a controlled way, a large percentage of the seeds and pods that have escaped the reel are carried to the draper belt and feed to the threshing system.

Comparison

With IAS

Comparison

Without IAS

Superior Solution for Sensitive Crops

IAS Advantages

- Specifically designed for harvesting very sensitive crops

- Maximizes yield by gently blowing dropping grains back to the belt

- All airlines integrated in the head - no exterior lines to damage pods